As a leading manufacturer of geomembrana, one of the most frequently asked questions we encounter is, “How long does it last?” This question is central to the industries relying on these versatile materials, from construction to environmental protection. The durability of geomembranes and their resistance to aging is not just a matter of longevity but a measure of their ability to deliver sustainable and reliable performance. In this blog, we will explore the factors influencing the lifespan of geomembrana, focusing on the properties of hdpe geomembrane liners, manufacturing advancements, and the growing demand for wholesale geomembrane products.

I. What Makes Geomembrana Durable?

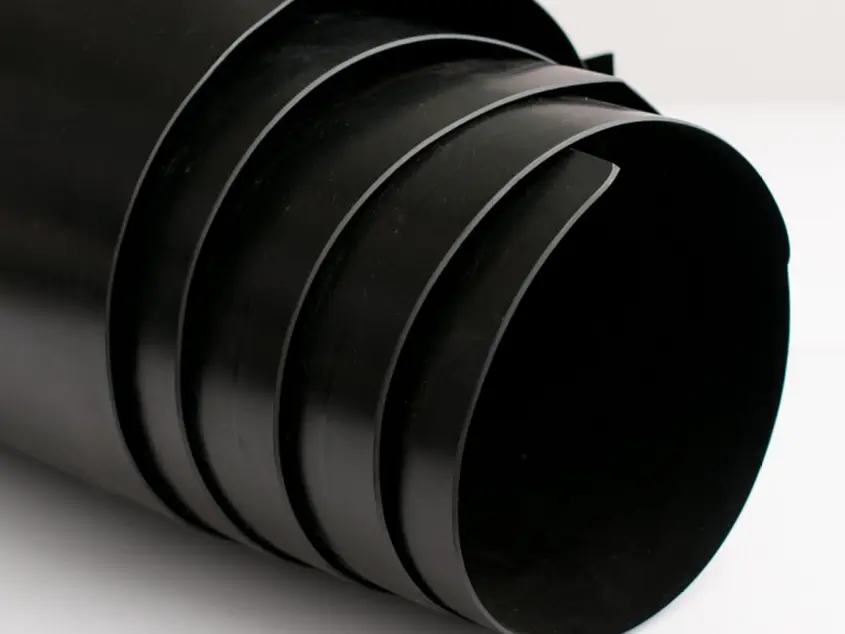

The durability of geomembrana lies in its chemical composition, production quality, and ability to resist external stressors. HDPE (High-Density Polyethylene) geomembrane liners, for example, are highly valued for their toughness, flexibility, and exceptional resistance to chemicals and ultraviolet (UV) radiation.

Durability is defined by a geomembrana’s ability to maintain its structural integrity over time. Factors contributing to this include:

– Material Composition: HDPE is the primary material used in most geomembrana products because of its superior durability compared to other plastics.

– Thickness: Thicker geomembranes generally exhibit greater resistance to punctures and environmental degradation.

– UV Resistance: Prolonged exposure to sunlight can degrade polymers. High-quality hdpe geomembrane liners are often treated with UV inhibitors to slow down the aging process.

– Stress Crack Resistance: Stress cracks are a common failure mode for many polymers. HDPE geomembrane liners are engineered to resist this phenomenon, enhancing their lifespan.

Properly manufactured and installed geomembrana can last decades, making them a cost-effective and sustainable solution for industrial and environmental applications.

II. Longevity in Different Applications

Geomembrana products are used in a variety of industries, each posing unique environmental and mechanical challenges. These applications include waste containment, water management, and infrastructure projects. Below, we’ll analyze how geomembrana performs in these contexts.

1. Landfill Liners and Waste Containment

Landfills require geomembrana to act as a barrier, preventing leachate from contaminating surrounding soil and groundwater. In this application, the material must resist exposure to harsh chemicals, fluctuating temperatures, and heavy loads. The lifespan of HDPE geomembrane liners in landfill applications can exceed 30 years, provided the product is installed correctly and maintained well.

2. Water Reservoirs and Canals

In water management, geomembrana prevents water loss due to seepage and protects the reservoir or canal bed. HDPE geomembrane liners are ideal for these projects due to their impermeability and chemical resistance. With proper UV stabilization, they can last up to 50 years in outdoor applications.

3. Mining and Industrial Use

Mining operations involve the storage and management of hazardous materials. Geomembrana plays a crucial role in lining ponds, tanks, and tailings dams. HDPE geomembrane liners, known for their chemical resistance, can provide reliable service for decades under extreme conditions.

4. Infrastructure and Roads

Geomembrana is increasingly being used in infrastructure projects, including road stabilization and tunnel waterproofing. The durability of HDPE geomembrane liners ensures their performance under high mechanical stress and exposure to environmental factors.

III. Aging Resistance: Key to Extended Lifespan

The aging resistance of geomembrana is what sets apart premium-quality products from substandard ones. Aging refers to the gradual degradation of a material’s properties over time due to environmental exposure. For geomembrana, this primarily includes UV radiation, thermal oxidation, and chemical attack.

1. UV Protection

HDPE geomembrane liners are treated with carbon black and other additives to enhance their resistance to UV rays. This is crucial for applications where the material is exposed to direct sunlight for extended periods.

2. Antioxidants

Oxidation is another major factor in the aging of geomembrana. High-quality geomembrana incorporates antioxidants during the manufacturing process, slowing down the degradation caused by oxygen and heat.

3. Chemical Resistance

Many geomembrane applications involve exposure to aggressive chemicals. HDPE geomembrane liners offer superior chemical resistance, which is critical for their long-term performance in waste containment and industrial settings.

4. Proper Installation and Maintenance

Even the most durable geomembrana can fail prematurely if not installed correctly. Regular inspections and proper maintenance further extend the product’s lifespan, ensuring optimal performance for years to come.

IV. Wholesale Geomembrane: Meeting Market Demands

With the increasing global demand for geomembrana, manufacturers are focusing on producing high-quality and cost-effective solutions for various applications. Wholesale geomembrane products are becoming more popular, offering businesses the chance to purchase these materials in bulk at competitive prices. Wholesale options make geomembrana accessible to smaller enterprises while ensuring consistent quality.

At the same time, innovations in manufacturing technology are enabling producers to deliver products that meet or exceed industry standards. This includes the development of advanced HDPE geomembrane liners with improved stress crack resistance, chemical stability, and UV protection.

V. Conclusion: Why Choose HDPE Geomembrane Liners?

The lifespan of a geomembrana is determined by its material properties, installation quality, and environmental conditions. HDPE geomembrane liners are at the forefront of the industry, offering unmatched durability and aging resistance for applications ranging from landfills to water reservoirs. By choosing the right product and ensuring proper installation and maintenance, businesses can benefit from geomembrana solutions that last decades.

For companies looking to purchase reliable geomembrana in bulk, wholesale geomembrane options provide an excellent balance of cost-efficiency and quality. Whether you’re a contractor or an end-user, investing in high-quality geomembrana ensures the success and longevity of your projects.

In conclusion, the durability and aging resistance of geomembrana make it an invaluable material for industries worldwide. As a manufacturer, we take pride in delivering products that meet the highest standards, ensuring your projects remain safe and sustainable for decades to come.